Transformers utilize the principle of electromagnetic induction to step up or step down voltage, thereby ensuring efficient transmission and distribution of electrical power. Their applications span various fields including power transmission and distribution, welding, and rectification.

Transformers can be categorized by purpose: - Power transformers for transmission and distribution, including step-up and step-down transformers; - Special-purpose transformers for specific applications, such as welding transformers, rectifier transformers, furnace transformers, and medium-frequency transformers; - Instrument transformers for measurement, including current transformers, voltage transformers, and autotransformers (voltage regulators); - Low-power transformers for automatic control systems; Impedance transformers for communication systems, etc.

1. Working Principle of Transformers

The core principle of a transformer is electromagnetic induction: a changing magnetic field generated by the primary winding induces a voltage in the secondary winding. This process enables voltage conversion between different levels, achieving step-up or step-down effects.

Primary winding: Connected to the power source, generating the changing magnetic field.

Secondary winding: Induces voltage from the changing magnetic field to supply the load.

Transformer design relies on the core, which primarily transmits and intensifies the magnetic field strength, while the windings utilize the interaction between current and magnetic field to generate voltage.

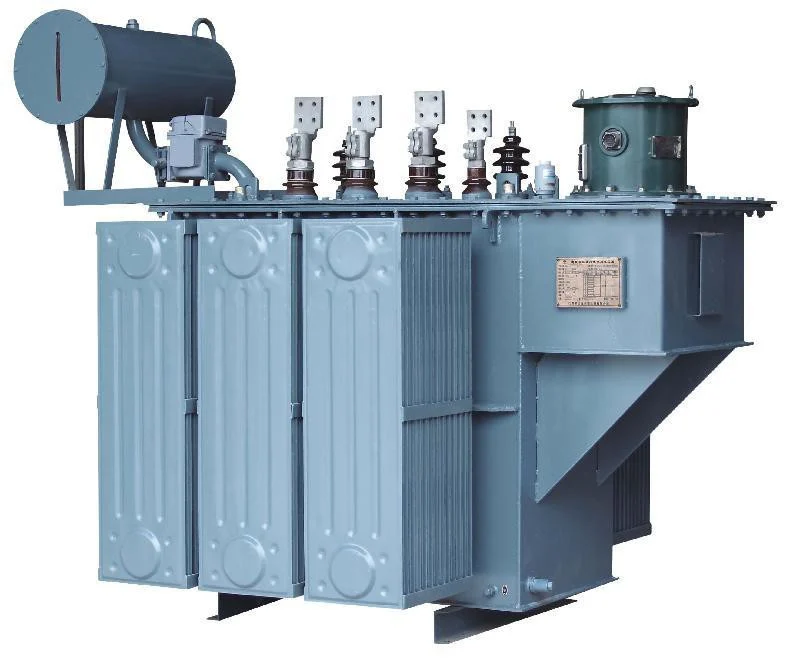

2. Structural Components of Transformers

The structure of a transformer primarily consists of the following key components:

Core: Typically constructed from laminated silicon steel sheets, it provides a path for magnetic flux and enhances magnetic field conduction. Core quality directly impacts transformer efficiency and power loss.

Windings: Made of conductive materials (usually copper or aluminum). The turns ratio between primary and secondary windings directly determines the transformer's voltage transformation ratio.

During design, a reasonable turn ratio is fundamental to ensuring stable voltage conversion.

3. Working Principle and Structure of Low-Frequency Transformers

A low-frequency transformer is a single-winding device. When used as a step-down transformer, voltage is applied only to a portion of the winding. When a segment of the winding is extracted as the secondary winding for step-up operation, voltage is applied to only part of the winding's turns. The remaining portion is referred to as a series cluster. Compared to traditional transformers, CCC transformers offer compact dimensions, high efficiency, large capacity, and high operating frequency. Furthermore, with the development trends in power distribution systems, increasing power levels, and expanding distribution equipment capacity, self-compensating capacitors have gained widespread application due to their advantages of large capacity, low power consumption, and low cost.

Low-frequency transformers are extensively used in power transmission and distribution systems. They feature:

Compact Design: Typically miniaturized, low-frequency transformers save space and suit constrained installation environments.

High Efficiency: Their smaller capacity requires less material (e.g., silicon steel sheets and copper wire), reducing manufacturing costs and enhancing operational efficiency.

High Short-Circuit Impedance: Low-frequency transformers exhibit strong short-circuit resistance, enhancing system stability and preventing outages caused by short circuits.

4. Market Demand and Development Trends for Low-Frequency Transformers

Energy Efficiency and Environmental Protection: Increasingly stringent environmental regulations drive low-frequency transformers toward lower energy consumption and greater eco-friendliness. New materials like low-loss cores and high-efficiency conductive coils will further enhance transformer efficiency while reducing environmental impact.

Intelligent Systems: With the advancement of IoT technology, transformers will integrate with smart monitoring systems to provide real-time equipment status tracking, predict maintenance needs, optimize schedules, and minimize downtime.

High-Frequency Applications: Beyond traditional low-frequency power transformers, demand is growing for high-frequency power systems, particularly in communications and computing sectors.

Enhancing Core Material Quality: Selecting low-loss, high-permeability core materials effectively reduces energy loss and improves transformer efficiency.

Optimizing Winding Design: By rationally designing the winding turn ratio and wiring configuration, transformer load capacity can be enhanced, equipment temperature rise reduced, and stability improved.

Improving Insulation Systems: Adopting high-performance insulation materials enhances transformer safety and extends service life. 6. Market Competition and Development Prospects for Transformers.

As a professional manufacturer and wholesaler of charging adapters, Macable offers a wide range of low-voltage transformers that comply with international certification standards to meet the needs of global consumers. We are committed to providing efficient, safe, and environmentally-friendly charging solutions, offering users a smarter and more convenient charging experience.